Loading... Please wait...

Loading... Please wait...- My Account

Blog - Express Chem

Benco VS PowderStrip

Posted by Chad Sturm on 11th Apr 2016

Let me begin by saying that this is not a “which is better” product review. At MIT Powder Coatings we are proud to offer both PowderStrip and Benco products. We do however get asked quite often, “What’s the difference between Benco B17 and PowderStrip?” I’m going to do my best to answer that question.

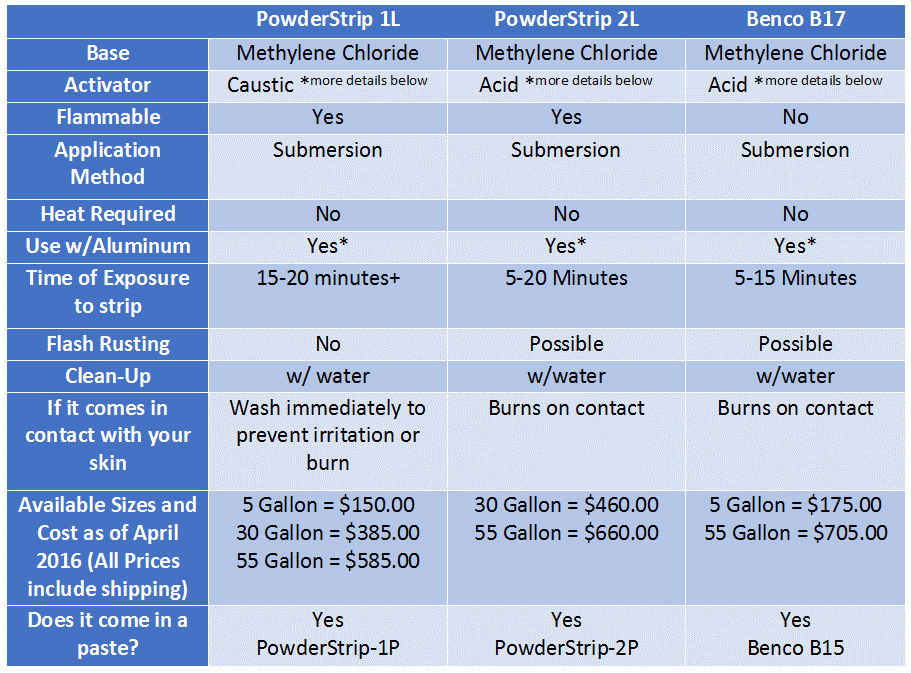

I’m comparing 3 products today: Benco B17, PowderStrip 1L, and PowderStrip 2L. Check out this side by side chart:

Key differences:

- The activator: A caustic activator will break down and dissolve the coating. The coating residue remains in the stripper and with usage over time may decrease the effectiveness of the stripper. An acid activator will swell the coating and delaminate it from the substrate. The coating residue “sheets” off and can be easily removed from the dip tank (although it doesn’t need to be). The stripped coating can then be rinsed with water to decontaminate the residue.

- Flammable vs Non-Flammable: All products require proper ventilation when being used. If you are in a facility with sparks or open flames this is definitely a consideration.

- All can be used with aluminum or other soft metals but over exposure can cause etching.

- B17 and PowderStrip 2L may require a rust inhibitor if the part is not being coated right away.

- Proper safety equipment should be worn when using all of these products. However, accidents do happen and the PowderStrip 1L is the most forgiving when it comes in contact with skin.

Ultimately the end result is 3 great products that produce excellent results; a clean, stripped part.